Blog

HARP2 Integrates into PACE Observatory

Posted on Thursday, November 17, 2022 at 12:00:00Nine dots of glue. Three prisms. One flexible pedestal. Glass everywhere.

Those were some of the things the HARP2 team saw after conducting vibration testing back in February.

Things didn't go well.

"We were hoping everything was ok," said Ron Zellar, systems engineer on the PACE team, "After we took a panel off to see inside, I remember one of the UMBC engineers saying 'oh my gosh there's glass everywhere'."

He was right. The testing of HARP2 had failed, taking the team back to the drawing board.

Operation "HARP 2.1," the team joked, was in full effect.

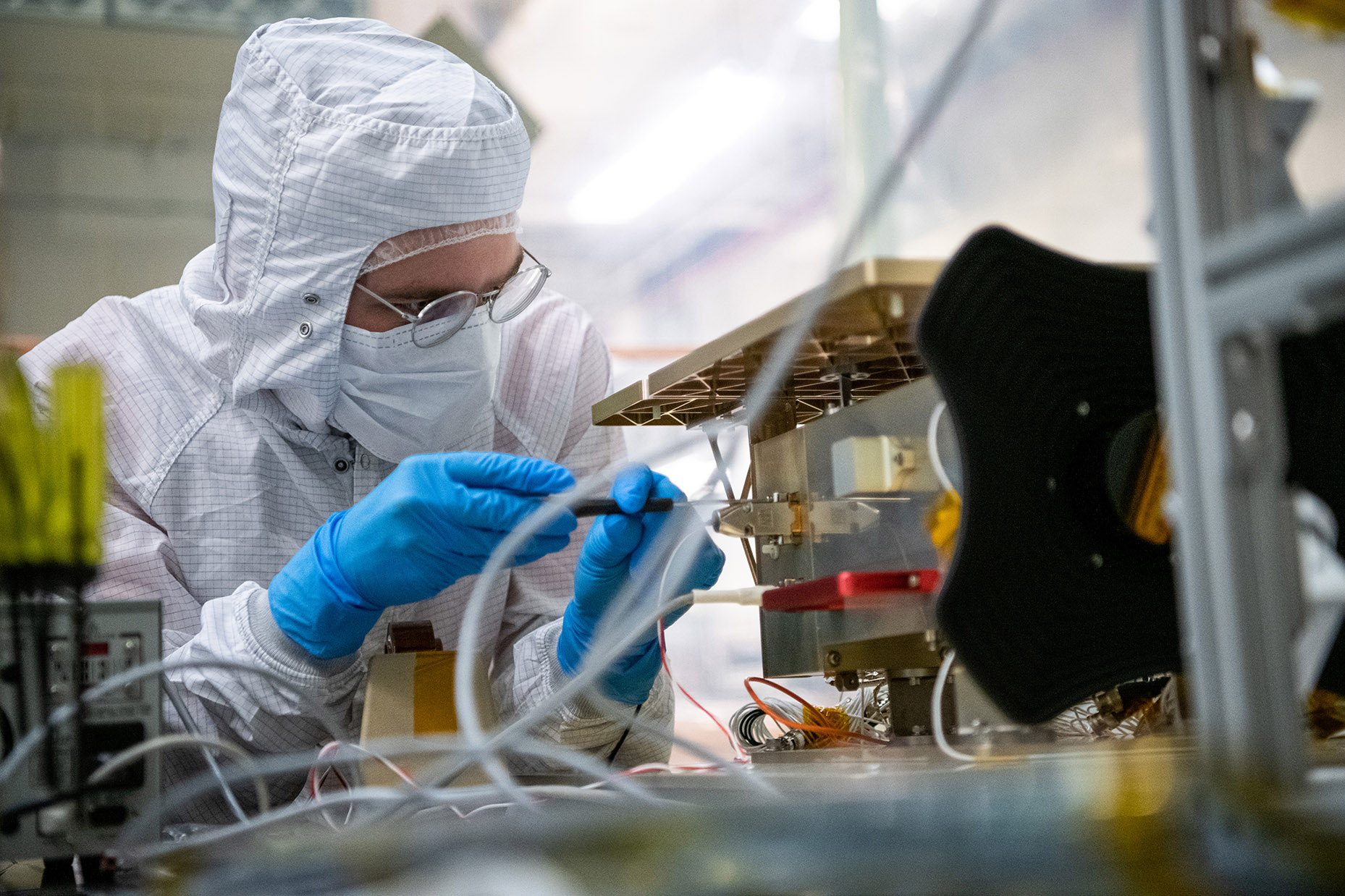

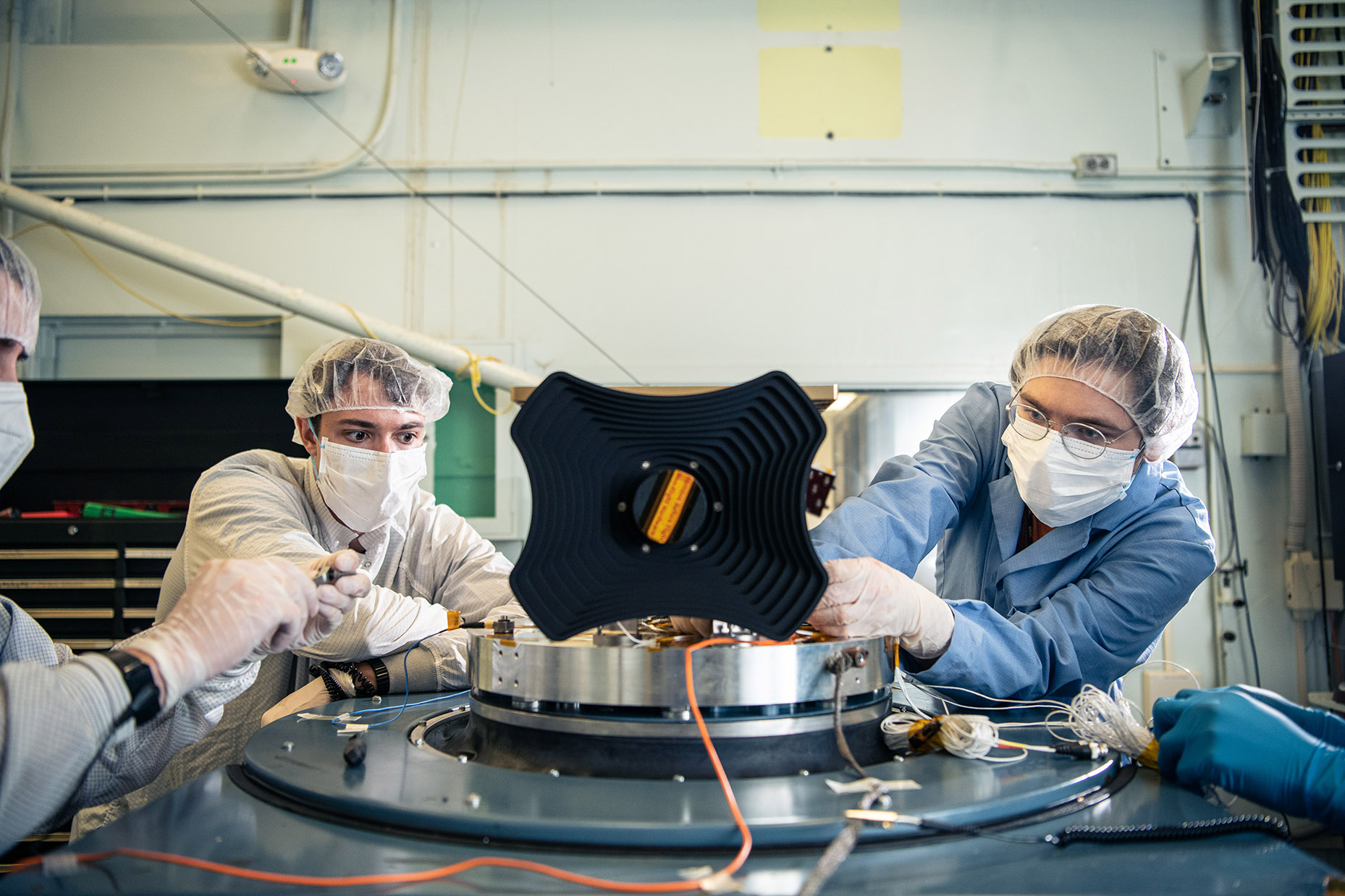

Despite the setback, everyone got to work. This past October, HARP2 was successfully integrated into the PACE spacecraft.

HARP2 is a wide angle imaging polarimeter designed to measure aerosol particles and clouds, as well as properties of land and water surfaces. It is one of two polarimeters, along with SPEXone, that will launch on the PACE spacecraft in January 2024.

"It's a scientific instrument that looks down on the Earth through the Earth's atmosphere and detects what the scientists call aerosols (tiny dust particles)," Zellar said. "Understanding aerosols in the Earth's atmosphere is important because it contributes to our understanding of the global climate model."

The Fail

HARP2 was designed and built in partnership with UMBC's Earth and Space Institute. After finishing building HARP2 earlier this year, the engineering team conducted a vibration test of the instrument. This involves shaking the instrument to simulate launch forces in three axes (X, Y, Z).

Learn about how UMBC built HARP2 »

The X- and Z-axis tests went fine. When they tested HARP2 on the Y axis, Zellar said things went differently. The prisms that are at the heart of the instrument became unbonded from their mounting pedestal and bounced around the inside of the instrument.

"We knew right away something had broken," he said. Worse yet, the loose prism damaged other components inside the instrument. "I would consider this one of the worst vibration failures I've seen."

After testing, the team opened up one of the instrument's panels and saw the extent of the damage. It was taken back to UMBC and an investigation was opened to answer questions like "Was the glue not strong enough?" and "Was there contamination?".

PACE members said the point of any vibration test is to uncover weaknesses.

"Instead of treating these incidents as 'failures,' we like to think of these anomalies as successful tests in that we learned something and can usually fix the problems and re-test," said Gary Davis, PACE's Mission Systems Lead. "Typically, this results in a better, more robust set of hardware that has a much higher chance of surviving the real flight environment."

Zellar was asked to head the failure review board to learn more. A major concern for PACE was whether the problem could be corrected and the instrument reassembled in time to be integrated with the spacecraft. But just two weeks after the failure, an underlying issue was starting to come into focus.

"The prisms were epoxied to a pedestal that was attached at its base to an instrument structure. When the pedestal was in the vibration test, where it was being shaken, it was acting like a whip," Zellar said.

The whip caused the prisms to accelerate faster than the vibration table itself.

"It had this whipsaw effect on the prisms. The glue that held the prisms to the pedestal did not break. The prisms broke free because the glass failed," he added. "The forces were so high on the prisms, they fractured at the edge of the glue spots. But the glue itself was good. The root cause of the problem was amplifying the acceleration of the vibration test."

New Design

With the problem identified, UMBC and PACE members got to work coming up with a new design. Zellar said they consulted with experts at NASA Goddard Space Flight Center (GSFC) on ways to make things sturdier.

"Experts told us to coat the entire surface with glue," Zellar said. "Before that, UMBC had just used three dots of glue per prism. There were a total of three prisms, so nine dots total holding it together."

In the new design, experts said there needed to be a complete coating of epoxy glue across the pedestal, essentially everywhere the glass touched the pedestal. The addition of glass beads in the epoxy would keep the epoxy from squeezing out from underneath when the prism was pushed down.

While the new adhesive application process was being worked on, the UMBC team created a stronger, "beefier" pedestal design. With spare prisms and spare parts, the team executed a validation test to see if the new design would work.

"We took the new design back to Goddard for testing," Zellar said. "At the end of April we conducted an engineering test unit vibration test - on all three axes - at the same levels we did back in February. It passed with flying colors. Everything looked great."

After the successful test, the UMBC started reassembling the flight unit with confidence the new design would survive another vibration test.

HARP2 was brought to GSFC for a second time and environmental testing resumed earlier this year. This time around, the team was "99 percent" confident it would pass.

Their hunch was right. HARP2 passed testing.

"After you have an extreme vibration failure, you question whether your design is going to be worthy of a flight," Zellar said. "Then you pour yourself into the next two to three months to come up with something better. I would say yeah, that's a comeback story."

After its successful vibration testing, HARP2 had a few more environmental tests before it was officially integrated into the PACE spacecraft.

Zellar said there was a real possibility HARP2 was not going to launch considering the tight time frame to fix things. He credited great teamwork within PACE and UMBC teams for making things possible.

Jeremy Werdell, PACE's Project Scientist, said he had no doubt a solution would be found especially with their UMBC partners.

"I've known the UMBC players for years and, not surprisingly, it has been a pleasure to work with them on PACE. HARP2 is an exciting instrument that should help change the way we look at our home planet. It has capabilities for cloud studies that go well beyond what can be accomplished by the rest of the observatory." he said.

HARP2 is preceded by its aircraft version (AirHARP) and by the HARP 3U CubeSat satellite that was successfully launched from the International Space Station on Feb. 19, 2020.

PACE is NASA's Plankton, Aerosol, Cloud, ocean Ecosystem mission, scheduled to launch in 2024, extending and improving NASA's over 20-year record of satellite observations of global ocean biology, aerosols (tiny particles suspended in the atmosphere), and clouds.